Extraction of Wood Sugar

The initial stage of the technology is the process called auto-hydrolysis. Wood is cooked with steam until the hemicellulose is hydrolysed. This turns the hemicellulose in the wood into water soluble sugars. The liquid sugars are thereafter separated from the remaining fibrous solid material consisting mainly of cellulose and lignin.

There are in principles several technical solutions for using the process, with different machinery at some stages. Our main goals when choosing the favourable technical setup is energy efficiency and reliability.

The wood sugar is in liquid form, typically with a similar concentration as molasses from sugar cane of beet molasses, in the range of 70 – 75% dry matter.

The processing of the wood pulp after dewatering to pellets is done as manufacturing ordinary wood pellets. The pellets made from the wood pulp after dewatering have higher energy content than ordinary wood pellets, higher bulk density, and very low ash content. More about these pellets.

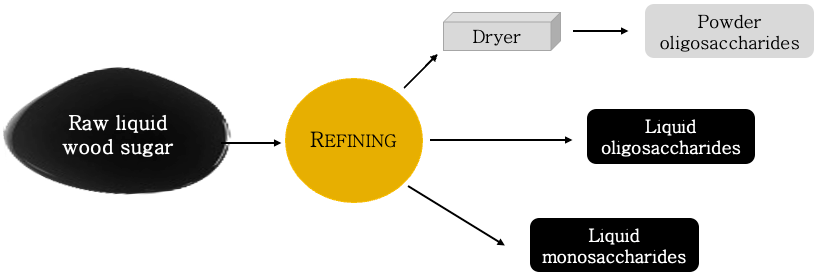

Refining Wood Sugar

The refining of the wood sugar after extraction consists of several steps that enhances the purity of the products. Within the main groups of products shown below there can be a variety of specialised products.