Prebiotic Oligosaccharides as Additives in Feed

Oligosaccharides have prebiotic properties, having beneficial effects for the gut health of fish, animals, poultry and humans. There is a global market oligosaccharides as prebiotics, so far mainly with products made from other plants than wood. This market for feed prebiotics is expected to grow very fast in the coming years, not the least because prebiotics are seen as an alternative to high use of growth antibiotics.

This is the most valuable use of wood sugars today. The requirement is that the sugar should be refined to oligosaccharides with high purity, something we have reached in pilot scale production.

Wood sugar for humans

Oligosaccharides are also beneficial as prebiotics for human consumption. It will take years to obtain the necessary approvals from the relevant authorities for this purpose. This market is, however, a very promising long term opportunity.

Xylose is in use as low calorie sweetener. Most of the xylose in use today is from non-wood sources, but can also be refined from wood sugar.

Ingredient in Feed

Wood sugar can be used as ingredient in feed for ruminants, substituting molasses from sugar cane or beet sugar. Ruminants (cattle and sheep) can digest both mono- and oligosaccharides.

Mono-gastric animals (pigs, horses etc) can digest the monosaccharides in wood sugar, but not the oligosaccharides.

Synergy with Wood Pellets Plants

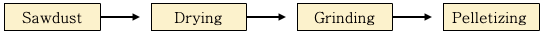

The most obvious beneficial combination is production of wood molasses in combination with a wood pellets plant. The typical process flow at a wood pellets plant is shown below:

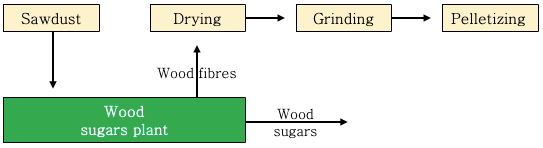

In combination with wood molasses, the first part of the flow changes to:

About 20% of the dry matter in the wood is extracted as wood sugar, while the remaining 80% are wood fibres mainly consisting of cellulose and lignin. The value of the wood sugars per unit of dry matter is way higher than the value of pellets, in recent years often about the double price.

The pellets made from the wood fibres after extraction of wood sugar are of a better quality than ordinary wood pellets. In addition, the drying costs are much lower, because the moisture of the wood fibres will be much lower than in the sawdust. More information here.